Electric submersible drainage pump, available in cast iron and stainless-steel alloys. Designed for use in mining, power plants and other industries that handle abrasive solids and water.

Data sheet:

Classification

Submersible electric pump

Electric motor

Three-phase squirrel cage motor

Speed: 2950 RPM

Insulation class: H

Start: Star-Delta

Max.number of starts per hour :12

Mechanical seals

Double

mechanical seal in oil chamber and water

Rotary seal material : silicon carbide

Stationary seal material : silicon carbide

Elastomers: Viton.

Discharge connection

6″H – 8″N (*)

Motor protection

Thermo-contacts in the winding

Protection: IP 68

Cable

2 cables 4G16+ 2×1.5mm2, 20m (*)

This pump must be connected to an external electrical cabinet

with adequate protections.

Bearings

Lower: Angular Contact Bearings

Upper: Cylindrical roller bearing

Limitations

Maximum submersion: 20 m

Maximum liquid temperature: 40 °C (104 °F)

Liquid pH range: 6 –11.

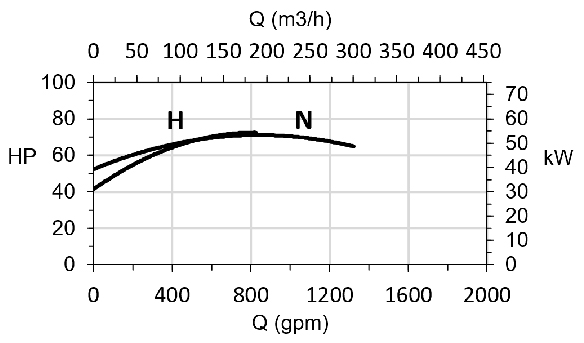

50HZ | H | N |

|---|---|---|

Power, HP (KW) | 52 / 70 | 52 / 70 |

Voltage (V) | 380 / 400 / 500 | 380 / 400 / 500 |

Nominal Current (A) | 85,9 / 82 / 65,3 | 85,9 / 82 / 65,3 |

Weight, lb (kg) | 649 | 649 |

Max. height, inch (mm) | 1481 | 1481 |

Max. diameter, inch (mm) | 627 | 527 |

Discharge, inch (mm) | 6″ | 8″ |

Strainer opening Ø, inch (mm) | 12 | 12 |

Cover | Cast iron |

Cylinder | Carbon Steel |

Strainer | Carbon Steel. |

Impeller | High Chrome Steel / Stainless steel |

Diffusers | Cast iron + PU / High chrome steel

|

Shaft | Stainless Steel |

Screws/Nuts | Stainless Steel |